Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

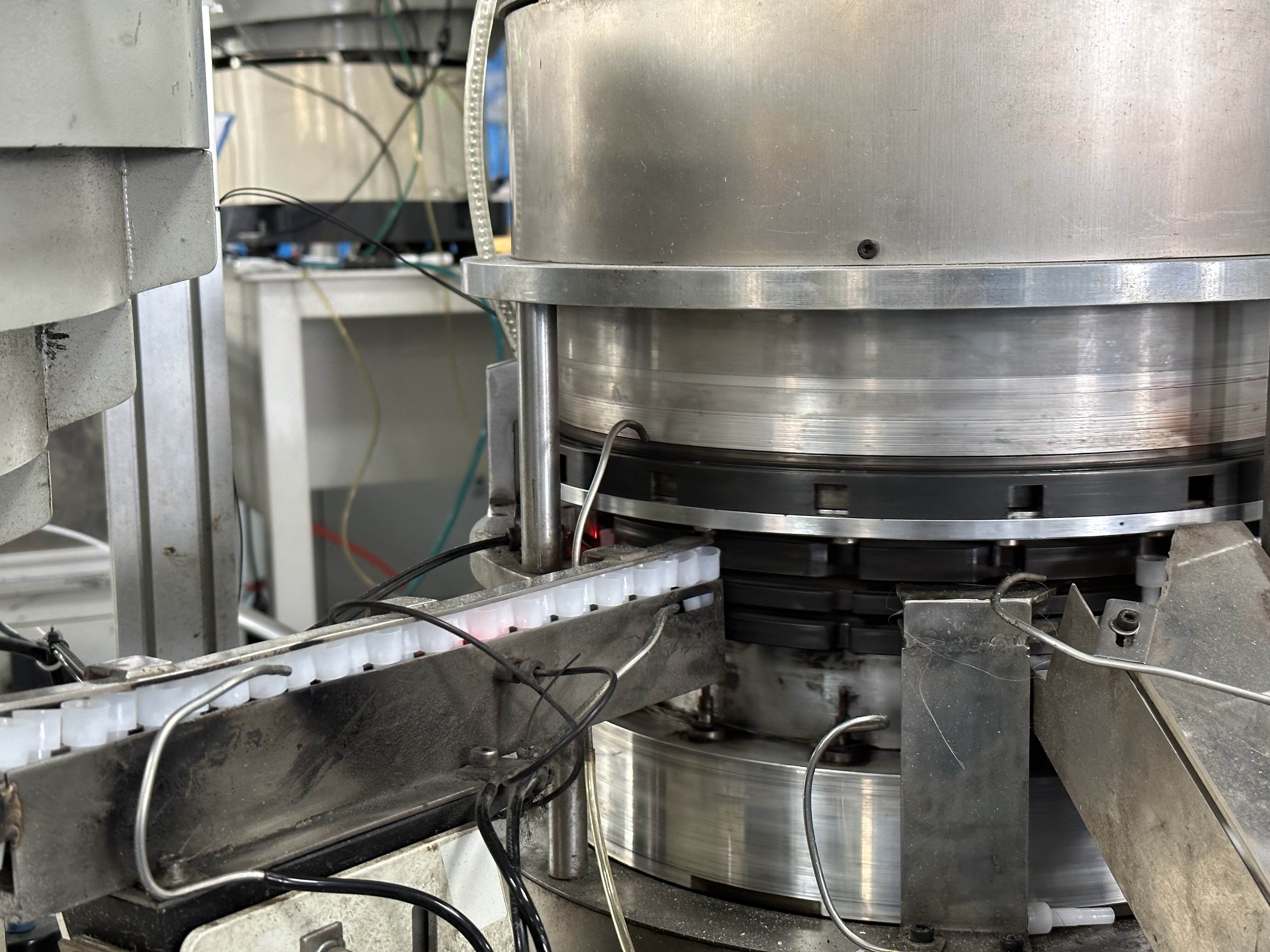

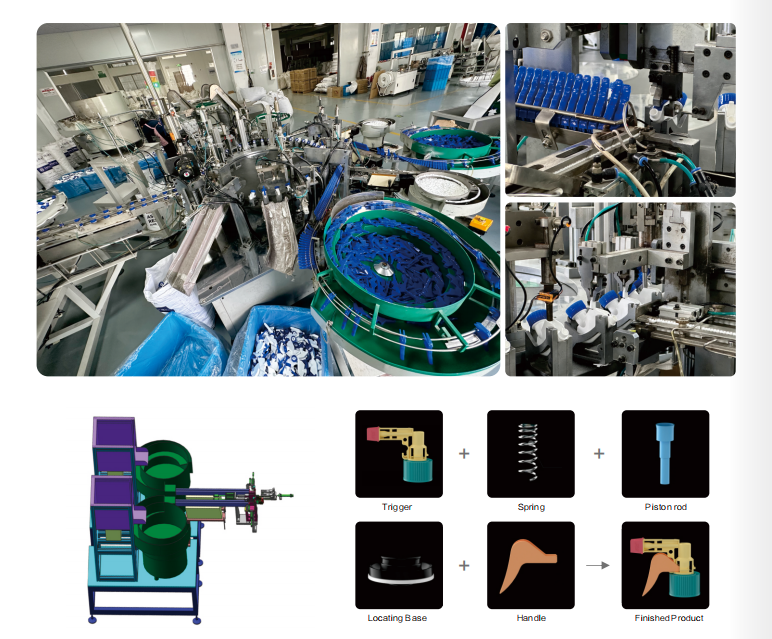

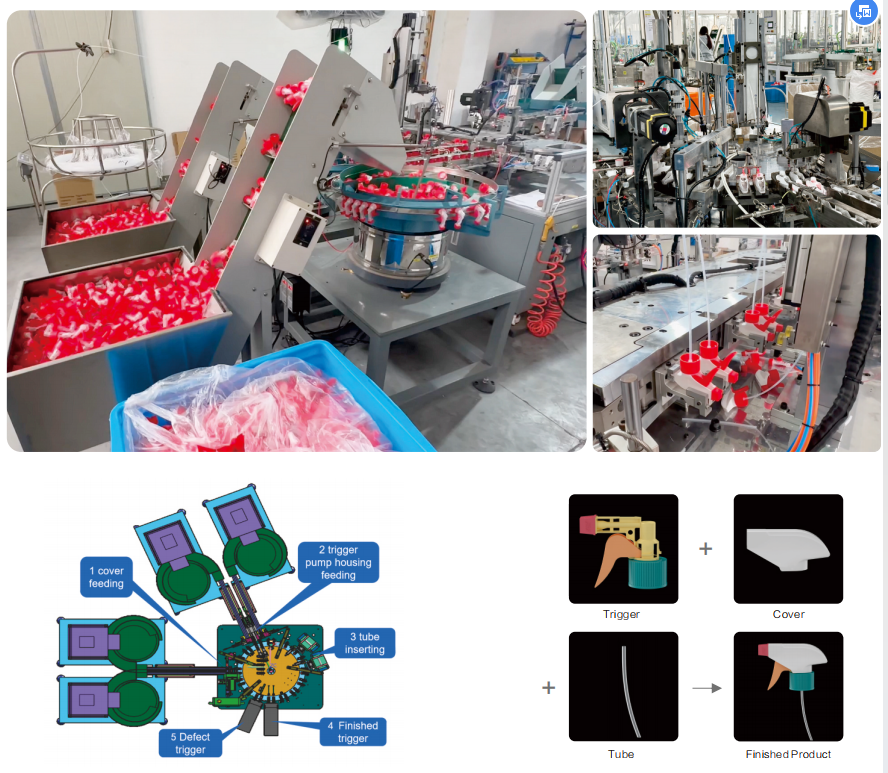

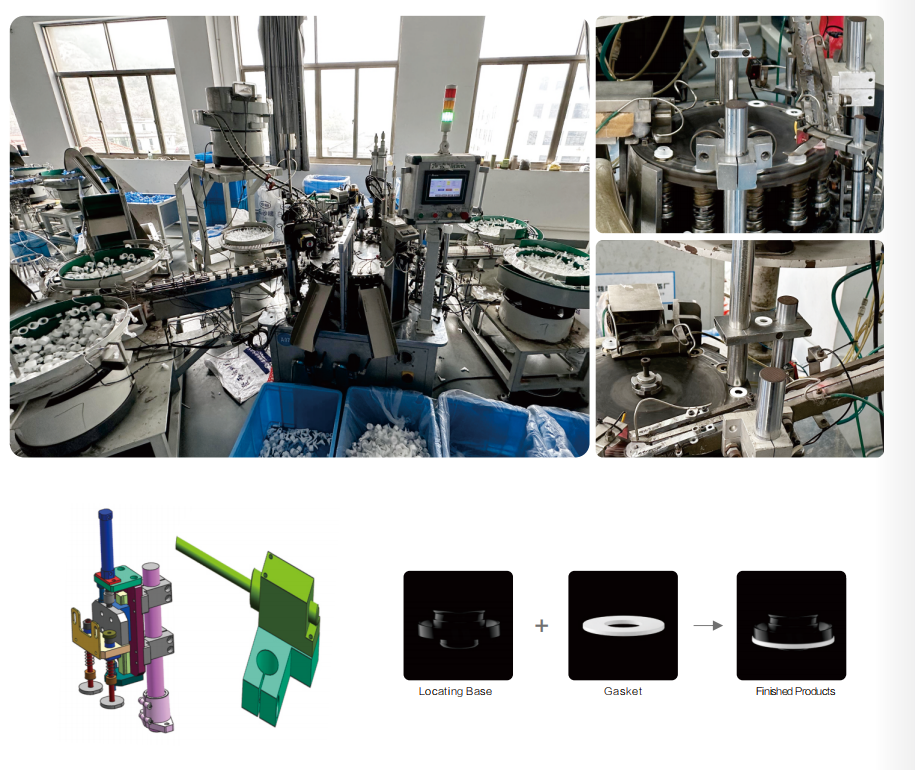

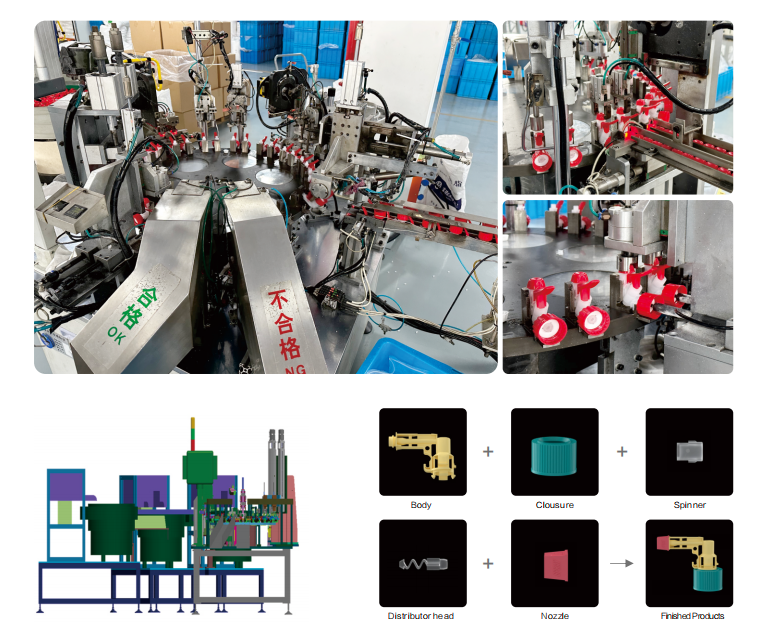

SR-TSM-01 Piston & Glass ball Assembly Machine

The positioning base of the trigger sprayer and the glass ball are installed, and the production capacity can reach 110-120 pieces per minute.

- Product Details

-

Download

Description

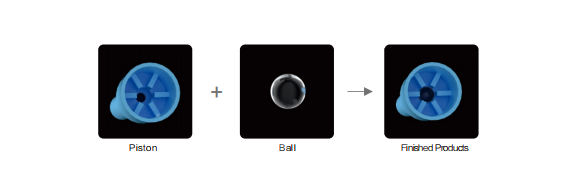

Parts automatically assembled by the machine: Piston Rod,Ball

Product Specification

| Main Component Configuration List | |||

|---|---|---|---|

| Project | Brand | Place of Origin | Remarks |

| PLC | Delta / Siemens | Taiwan, China / Germany | Customize |

| Servo Motor | Delta | Taiwan, China | Customize |

| Stepping Motor | Leisai / NBNCKJ / Inovance | China | Customize |

| Frequency Conversion Motor | Limin | China | Customize |

| Touch Panel | Weinview | China | Customize |

| Module | Dazzle | China | Customize |

| Guide Rail | Hiwin | Taiwan, China | Customize |

| Cylinder | Airtac / SMC / Festo | Taiwan, China / Japan / Germany | Customize |

| Barometer | Keyence | Japan | Customize |

| Non-Standard Component | Customize | China | Customize |

Product Features and Advantages

The piston uses the rotation of the vibrating disk to achieve feeding, and the material is smoothly transported to the piston station, and then the inspection process is carried out. After the inspection is completed, the rotating disk continues to operate, and the glass balls are transported through the pipeline and installed with the piston at the corresponding position. After the installation is completed, the rotating disk rotates again, and the finished and defective products are selected for the assembled products. After the selection process is completed, the rotating disk continues to rotate, and product inspection is carried out at the production station. If the product is not detected at the production station, the equipment will maintain normal operation; if the product is detected, the equipment will immediately trigger the error mechanism and automatically perform adjustment operations to ensure the smoothness and stability of the production process.

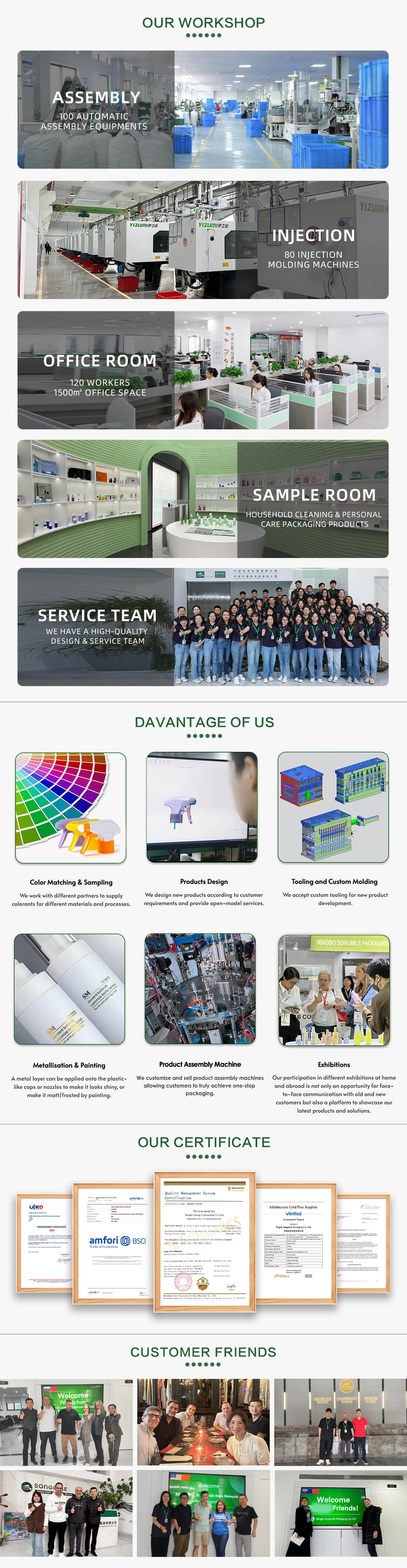

Why Choose Us?

1: Are you a trade company or an manufacturing factory?

We are the Industry and trade integration company, we have our own manufactory.

2: How to get a quotation and start business relationship with your company?

First we need the photos of the item which you need the machine to assembl it, then we will send a information collection sheet to you, after all the informaton confirmed, we will send our quotation to you along with the delivery time and design drawing.

3: What's the minimum order quantity?

Our MOQ is 1 set of machine or one production line, we also sell product's mould as package, more quantity more discount.

4: Can you make customised automatic assembly machines(line)?

Yes, we can, and we are experienced in manufacturing customised automatic assembly machines (line).

5: What's the delivery time?

Normally the delivery time is 2-3 months.

6: How about the payment terms?

50% in advance,40% after machine finished, and balance 10% before delivering. T/T, Irrevocable L/C at sight are all acceptable

7: Do you provide on-site installation and Commissioning services?

Yes, we can provide on-site installation and Commissioning services, but the buyer have to bear the trip air tickets, accommodation, and labor subsidies,etc.

Please let me know if you have any questions, don't leave silently...

Download

-

Catalog of SONGROCK Machine 6.7M.pdf

Download Catalog of SONGROCK Machine 6.7M.pdf